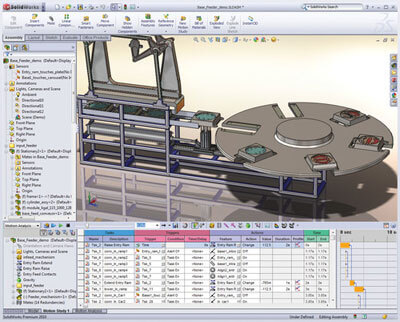

Easily simulate complex machine operations using event-based motion analysis with SOLIDWORKS Simulation and validate the sequencing of the design to ensure correct operation, product quality, and safety. See how your product would move in the real world and measure the forces and loads while you design, helping you correctly size the motors and the structure and confirm the timing.

Easily simulate complex machine operations using event-based motion analysis with SOLIDWORKS Simulation and validate the sequencing of the design to ensure correct operation, product quality, and safety. See how your product would move in the real world and measure the forces and loads while you design, helping you correctly size the motors and the structure and confirm the timing.

Tightly integrated with SOLIDWORKS CAD, event-based motion analysis using SOLIDWORKS Simulation can be a regular part of your design process—reducing the need for costly prototypes, eliminating rework or delays, and saving time and development costs.

Event-Based Motion Analysis Overview

In many cases, machine operation is based on triggers and sensors that activate machine action, such as a parcel being automatically sorted. Event-based motion is a complementary approach to solving kinematic and dynamic rigid body problems using SOLIDWORKS Motion, and has been developed to meet the needs of today’s more complex machine designs.

Event-based motion analysis is a solution method for rigid body motion where external actions (forces motion drivers) are triggered by the movement or the state of the assembly, rather than the time of the analysis. This approach has great advantages in the early stages of a design when product timings are not yet finalized.

Event-based motion can solve either kinematic or dynamic rigid body motion problems, and can simulate the effect of:

- Forces

- Springs

- Dampers

- Gravity

- Contact between components

- Bushings

Once the assembly motion has been calculated, a structural analysis of the components under the motion induced loads (accelerations and joint forces) can easily be carried out, either within the motion study or exported to a structural analysis study.