The new Objet500 Connex3 is the world's most versatile 3D printer, delivering unparalleled color product realism

New 3D Printer allows better decision making, improves design & manufacturing efficiencies and produces better products, faster

MINNEAPOLIS & REHOVOT, Israel--(BUSINESS WIRE)-- Stratasys Ltd. (NASDAQ: SSYS), a manufacturer of 3D printers and materials for personal use, prototyping, and production, today announced the launch of the ground-breaking Objet500 Connex3 Color Multi-material 3D Printer, the first and only 3D printer to combine colors with multi-material 3D printing.

Bike helmet 3D printed on the Objet500 Connex3 Color Multi-material 3D Printer in one print job using VeroCyan, VeroMagenta, and VeroYellow (Photo: Stratasys Ltd.)

A game-changer for product design, engineering and manufacturing processes, theObjet500 Connex3 Color Multi-material 3D Printer features a unique triple-jetting technology that combines droplets of three base materials to produce parts with virtually unlimited combinations of rigid, flexible, and transparent color materials as well as color digital materials - all in a single print run. This ability to achieve the characteristics of an assembled part without assembly or painting is a significant time-saver. It helps product manufacturers validate designs and make good decisions earlier before committing to manufacturing, and bring products to market faster.

"Stratasys' goal is to help our customers revolutionize their design and manufacturing processes," says Stratasys CEO David Reis. "I believe our new Objet500 Connex3 Color Multi-material 3D Printer will transform the way our customers design, engineer and manufacture new products. In general and with the Connex technology in particular, we will continue to push the envelope of what's possible in a 3D world."

Engineers at beta user Trek Bicycle in Waterloo, Wisconsin are using the Objet500 Connex3 Color Multi-material 3D Printer for assessment and testing of accessories like bike chain stay guards and handlebar grips prior to actual production. "The Objet500 Connex3 Color Multi-material 3D Printer changed the way we manufacture at Trek, augmenting our traditional, time-consuming CNC processes with fast, iterative and realistic prototyping and functional testing," says Mike Zeigle, manager of Trek's prototype development group.

"Now we produce bicycle parts that look and feel like production parts. We are particularly excited about 3D printing our models directly in color. This gives our designers the ability to graphically display color contact pressure map data on rider contact parts like seats and grips. We are also working on doing the same with FEA & CFD stress data on structural bike components," adds Zeigle.

Three Primary Color Materials Combine to Create a Spectrum of Vibrant Colors

Similar to a 2D inkjet printer, three color materials - VeroCyan, VeroMagenta and VeroYellow - are combined to produce hundreds of vivid colors. These color materials join Stratasys' extensive range of PolyJet photopolymer materials including digital materials, rigid, rubber-like, transparent, and high temperature materials to simulate standard and high temperature engineering plastics.

Another First: Flexible Materials in Color*

The Objet500 Connex3 Color Multi-material 3D Printer also features six palettes for new rubber-like Tango colors, ranging from opaque to transparent colors in various shore values to address markets such as automotive, consumer and sporting goods and fashion.*

"Since its introduction in 2007, the Objet Connex Multi-material 3D printing platform has paved the way for the development of advanced 3D printing materials with unique mechanical and thermal properties," says Stratasys VP of product marketing and sales operations Igal Zeitun. "The Objet500 Connex3 Color Multi-material 3D Printer produces models and parts using photopolymers in vivid colors so you can create colorful models from investigating concepts to pre-production pilot runs.

"As the first true multi-purpose 3D printer, we believe the Objet500 Connex3 Color Multi-material 3D Printer is in a league of its own, enabling you to dream up a product in the morning, and hold it in your hands by the afternoon, with the exact intended color, material properties and surface finish."

The Objet500 Connex3 Color Multi-material 3D Printer is commercially available today and is sold through Stratasys' extensive worldwide reseller network.

*The Flexible Materials in Color are expected to be commercially available in Q2/2014.

Additional Notes for Editors

The Technology Behind the Innovation

The Objet500 Connex3 Color Multi-material 3D Printer is based on proven Connex technology. Ideal for over-molding with Digital ABS and complex multi-material parts, the Objet500 Connex3 Color Multi-material 3D Printer is designed to enable designers, engineers and manufacturers to create models, molds and parts that match the characteristics of production parts. It 3D prints models and parts with the color, durability and surface finish of end products. This includes achieving excellent mechanical properties such as tensile strength, elongation at break, and multiple hardness shore values, which simulate high performance thermoplastics. It also allows overmolding using durable Digital ABS materials and introduces new Shore A values for Digital ABS, ranging from A27 to A95, a major advantage in manufacturing consumer products.

Featuring a large build envelope, the Objet500 Connex3 Color Multi-material 3D Printer is ideal for high capacity production. Print jobs can run with about 30kg of resin per cycle. True to the high resolutions available with PolyJet 3D printing technology, the Objet500 Connex3 Color Multi-material 3D Printer prints as fine as 16 micron layers for models with superior surface finish and ultra-fine detail.

More information about the Objet500 Connex3 Color Multi-material 3D Printer is available on the Stratasys website at: http://www.stratasys.com/Objet500Connex3.

A digital press kit for the Objet500 Connex3 Color Multi-material 3D Printer is available by visiting the Stratasys online newsroom which contains additional resources including an image gallery, a product video, customer story video, case study, white paper, brochure, color palette, and spec sheet.

Stratasys Ltd. (Nasdaq: SSYS), headquartered in Minneapolis, Minn. and Rehovot, Israel, manufactures 3D printers and materials for prototyping and production. The company's patented FDM® and PolyJetTM 3D Printing technologies produce prototypes and manufactured goods directly from 3D CAD files or other 3D content. Systems include 3D printers for idea development, prototyping and direct digital manufacturing. Stratasys subsidiaries include MakerBot and Solidscape, and the company operates the RedEye digital-manufacturing service. Stratasys has more than 1700 employees, holds over 500 granted or pending additive manufacturing patents globally, and has received more than 20 awards for its technology and leadership. Online at:www.stratasys.com or http://blog.stratasys.com.

Cautionary Statement Regarding Forward-Looking Statements

Certain information included or incorporated by reference in this press may be deemed to be "forward-looking statements" within the meaning of the Private Securities Litigation Reform Act of 1995, Section 27A of the Securities Act of 1933, and Section 21E of the Securities Exchange Act of 1934. Forward-looking statements are often characterized by the use of forward-looking terminology such as "may," "will," "expect," "anticipate," "estimate," "continue," "believe," "should," "intend," "project" or other similar words, but are not the only way these statements are identified. These forward-looking statements may include, but are not limited to, statements relating to the company's objectives, plans and strategies, statements regarding the company's products and their expected performance, statements that contain projections of results of operations or of financial condition (including, with respect to the MakerBot merger) and all statements (other than statements of historical facts) that address activities, events or developments that the company intends, expects, projects, believes or anticipates will or may occur in the future. Forward-looking statements are not guarantees of future performance and are subject to risks and uncertainties. The company has based these forward-looking statements on assumptions and assessments made by its management in light of their experience and their perception of historical trends, current conditions, expected future developments and other factors they believe to be appropriate. Important factors that could cause actual results, developments and business decisions to differ materially from those anticipated in these forward-looking statements include, among other things: the company's ability to efficiently and successfully integrate the operations of Stratasys, Inc. and Objet Ltd. after their merger as well as the ability to successfully integrate MakerBot into Stratasys; the overall global economic environment; the impact of competition and new technologies; general market, political and economic conditions in the countries in which the company operates; projected capital expenditures and liquidity; changes in the company's strategy; government regulations and approvals; changes in customers' budgeting priorities; litigation and regulatory proceedings; and those factors referred to under "Risk Factors", "Information on the Company", "Operating and Financial Review and Prospects", and generally in the company's annual report on Form 20-F for the year ended December 31, 2012 filed with the U.S. Securities and Exchange Commission and in other reports that the Company has filed with the SEC. Readers are urged to carefully review and consider the various disclosures made in the company's SEC reports, which are designed to advise interested parties of the risks and factors that may affect its business, financial condition, results of operations and prospects. Any forward-looking statements in this press release are made as of the date hereof, and the company undertakes no obligation to publicly update or revise any forward-looking statements, whether as a result of new information, future events or otherwise, except as required by law.

PolyJet, Connex, and Connex3 are trademarks, and Stratasys and Objet are registered trademarks of Stratasys Ltd. and or its subsidiaries or affiliates.

Attention Editors, if you publish reader-contact information, please use:

- USA 1-877-489-9449

- Europe/Middle East/Africa +49-7229-7772-0

- Asia Pacific +852 39448888

Photos/Multimedia Gallery Available: http://www.businesswire.com/multimedia/home/20140126005015/en/

Stratasys Media ContactsUSA

Weber Shandwick

Aaron Masterson, +1-952-346-6258

AMasterson@webershandwick.com

or

Europe

UK Bespoke

Jonathan Wake / Miguel Afonso, +44-1737-215200

stratasys@bespoke.co.uk

or

Stratasys

Arita Mattsoff, +972-(0)74-745-4000 (IL)

arita@stratasys.com

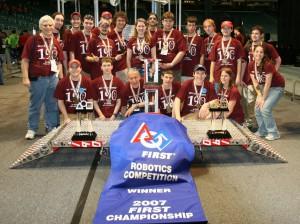

SolidWorks Sponsors US FIRST Robotics Teams

SolidWorks Sponsors US FIRST Robotics Teams

Teams can also get familiar with

Teams can also get familiar with