Create more innovative designs, improve product quality, and increase your productivity with SOLIDWORKS Simulation software. The powerful, intuitive user experience puts your focus on testing and optimizing your designs, instead of learning how to use the software.

Overview:

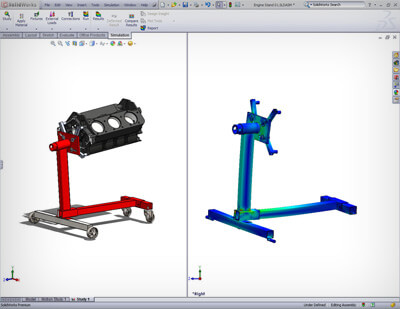

SOLIDWORKS Simulation provides a smooth simulation workflow so you can test your product while you design it. Fully embedded in SOLIDWORKS 3D CAD, the easy-to-use 3D virtual simulation capabilities eliminate tedious, time-consuming tasks as you:

- Perform simulations on the native 3D CAD model for parts and assemblies

- Perform “What’ if” scenarios to identify the best design alternatives

- Optimize your Design/Simulation process as any design change is automatically updated in SOLIDWORKS Simulation

- Leverage 3D CAD functionality (such as FeatureWorks, Geometry Analysis, and Simplify) to prepare your model for simulation

You learn fast with the intuitive user interface that is easy to use and designed to make you instantly productive. Extensive tutorials and support documentation help you progress quickly and transform your product development process:

- Quickly organize an analysis study using the Simulation study tree, with a familiar interface experience and functionality similar to the SOLIDWORKS FeatureManager tree

- Copy and paste your analysis set-up to define subsequent studies quickly and efficiently and test all your design ideas. Simply convert your static analysis into a non-linear or linear dynamic study carrying over the model set-up features.

- Customize Toolbar commands, organized by simulation function, for fast access

- Automate frequently used analysis features (such as load/restraint, contact condition, etc.) with the analysis library and define analysis features for specific design

environments or operating conditions - Record operations performed with the SOLIDWORKS Simulation user interface in a macro script

- Run selected Simulation studies automatically in a batch mode.

- Run a Simulation study offloaded on a different computer connected on your local network

Easily evaluate how your product will perform and move throughout its operational cycle with motion analysis using SOLIDWORKS Simulation. Visualize your product moving as it would in the real world and measure the forces and loads on your design. Plus, use the data to correctly size motors and create the ‘correct’ mechanism to ensure performance, product quality, and safety.

Tightly integrated with SOLIDWORKS CAD, motion analysis using SOLIDWORKS Simulation can be a regular part of your design process—reducing the need for costly prototypes, eliminating rework or delays, and saving time and development costs.

Motion Analysis Overview

Motion analysis is solved using a time-based approach for rigid body kinematic and dynamic problems. SOLIDWORKS Motion takes the designer beyond the free drag movement available in a CAD environment and into a true physical calculation of the forces and motions of an assembly as it would move under environmental loads (external forces) and/or internal loads (motors, springs, and dampers).

SOLIDWORKS Motion simulation can calculate the effect of:

- Forces

- Springs

- Dampers

- Gravity

- Contact between components

- Bushings

Once the assembly motion has been calculated, a structural analysis of the components under the motion-induced loads (accelerations and joint forces) can easily be carried out, either within the motion study or exported to a structural analysis study.

Linear stress analysis with SOLIDWORKS Simulation enables designers and engineers to quickly and efficiently validate quality, performance, and safety—all while creating their design.

Linear stress analysis with SOLIDWORKS Simulation enables designers and engineers to quickly and efficiently validate quality, performance, and safety—all while creating their design.

Tightly integrated with SOLIDWORKS CAD, linear stress analysis using SOLIDWORKS Simulation can be a regular part of your design process, reducing the need for costly prototypes, eliminating rework and delays, and saving time and development costs.

Linear Stress Analysis Overview

Linear stress analysis calculates the stresses and deformations of geometry given three basic assumptions:

- The part or assembly under load deforms with small rotations and displacements

- The product loading is static (ignores inertia) and constant over time

- The material has a constant stress strain relationship (Hooke’s law)

SOLIDWORKS Simulation uses finite element analysis (FEA) methods to discretize design components into solid, shell, or beam elements and uses linear stress analysis to determine the response of parts and assemblies due to the effect of:

- Forces

- Pressures

- Accelerations

- Temperatures

- Contact between components

- Loads can be imported from thermal, flow, and motion Simulation studies to perform multiphysics analysis.

In order to carry out stress analysis, component material data must be known. The standard SOLIDWORKS CAD material database is pre-populated with materials that can be used by SOLIDWORKS Simulation, and the database is easily customizable to include your particular material requirements.