3D print in high-impact engineering thermoplastic

3D print in high-impact engineering thermoplastic

For functional prototyping, tooling and low-volume manufacturing that requires superior impact strength, FDM Technology works with PC-ABS thermoplastic. This material offers the best features of two great FDM thermoplastics: the strength and heat resistance of PC and the flexibility of ABS. PC-ABS also exhibits excellent feature definition and surface finish.

3D Printing With PC-ABS Engineers and designers use PC-ABS in demanding applications like power-tool prototyping and industrial equipment manufacturing. 3D printing in real engineering thermoplastics results in stronger parts, more confident testing and prototypes that mimic the material properties of the final product. PC-ABS works with soluble support material, meaning support removal is hands-free and complex parts with deep internal cavities take no extra effort.

Your go-to FDM thermoplastic in 10 colors

Your go-to FDM thermoplastic in 10 colors

Mechanical strength and UV stability make ASA a great choice for functional prototyping. Ease of use makes it a top pick for iterative design. Outstanding aesthetics and ten fade-resistant colors make it an all-around favorite, even for end-use parts.

UV-Stable Prototyping ASA is a production-grade thermoplastic that works beautifully with FDM Technology. Available in 10 fade-resistant colors, ASA combines mechanical strength and UV stability with the best part aesthetics FDM technology has to offer. Build enduring prototypes to test fit, form and function – or produce practical production parts for outdoor use. From electrical housings and brackets to sporting goods and automotive prototypes, ASA will give your designs a place in the sun.

Colors include red, orange, yellow, green, dark blue, white, dark gray, light gray, ivory and black.

Build static-dissipative 3D printed parts

Build static-dissipative 3D printed parts

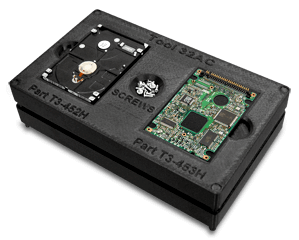

For applications where a static charge could damage components, impair performance, or cause an explosion, FDM Technology offers ABS-ESD7 static-dissipative thermoplastic. Engineers and designers can use FDM parts confidently to create jigs and fixtures for assembling electronic components. Functional prototypes for fuel storage and delivery products also benefit from static dissipation.

3D Printing With ABS-ESD7 lets electronics manufacturers expand the use of 3D printing onto the assembly line. Static dissipation also makes the material ideal for applications in the presence of powders, dust and mist that might otherwise be attracted to a plastic part. ABS-ESD7 standard FDM thermoplastic works with soluble support technology, so support removal is hands-free and complex parts require no extra effort.