3D Printing With High Temperature Material

3D Printing With High Temperature Material

High Temperature material (RGD525, white) combines heat resistance with exceptional dimensional stability. The material can simulate the thermal performance of engineering plastics and is ideal for testing applications such as hot-air flow or hot-water flow in pipes and faucets.

Objet High Temperature material has a heat deflection temperature of 63–67 C (145-153 F) upon removal from the printer. Thermal post treatment in a programmable oven can increase this to 75-80 C (167-176 F).

High-temperature parts with improved functional performance

Combining High Temperature material with Rubber-like materials produces varying Shore A values, gray shades and rigid functional materials with higher temperature resistance. The composite also enables printing high-temperature parts with over-molding.

Easy support removal

Increase productivity and gain even more design freedom with the ability to easily remove support material from delicate features and small cavities. Soluble support material (SUP706) empowers hands-free removal, plus improved manual or WaterJet removal. It is compatible with all PolyJet materials (except hearing aid and dental materials) and works on all Connex1, Connex2 and Connex3 systems.

A wide range of applications

- Form, fit and thermal functional testing of static parts

- High-definition parts requiring excellent surface quality

- Exhibition modeling under strong lighting conditions

- Heat resistant jigs and fixtures

- Post-processing including painting, gluing or metallization processes

- Models in transit

- Taps, pipes and household appliances

- Hot air and hot water testing

3D Printing With Digital ABS PolyJet Photopolymer

Digital ABS (fabricated inside the 3D printer from RGD515 and RGD535) is designed to simulate standard ABS plastics by combining high-temperature resistance with toughness. Digital ABS2 delivers those properties plus superior rigidity and toughness in walls thinner than 1.2 mm (.047 in.). Both materials are suitable for parts that require PolyJet technology’s highest possible impact resistance and shock absorption.

Easy support removal

Increase productivity and gain even more design freedom with the ability to easily remove support material from delicate features and small cavities. Soluble support material (SUP706) empowers hands-free removal, plus improved manual or WaterJet removal. It is compatible with all PolyJet materials (except hearing aid and dental materials) and works on all Objet1000 Plus and Connex3 systems.

A wide range of applications

- Functional prototypes

- Manufacturing tools

- Molds, including injection molds

- Snap-fit parts for high or low temperature use

- Electrical parts, casings, mobile phone casings

- Engine parts and covers

PolyJet Digital Materials

3D print in hundreds of composite materials

Create prototypes with a wide range of physical properties, colors and tones. Digital Materials empower you to bring your designs to life with realistic colors and textures faster than ever before.

What A Digital Material is the result of combining two or three PolyJet photopolymers in specific concentrations and microstructures to create a composite material with hybrid characteristics. All possible combinations are preconfigured and selectable in Objet Studio and PolyJet Studio Software to ensure predictable, repeatable results.

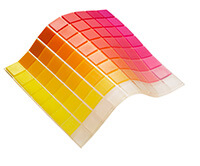

PolyJet flex palette demonstrating Digital Materials This example combines the translucent Rubber-like material Tango Plus with Rigid Opaque materials Vero Magenta and Vero Yellow. You can see that the hue varies from yellow to magenta with a range of oranges in between, while the color intensity and opacity fade as the flexibility increases.